Quality

Perfect Quality Verification System

We have prepared the system to respond to requests from our customers by developing various state-of-the-art testing facilities that can provide in-house technical consultation for the products to be used in various environments.

TOFLE OMEGA

FLEX CO., INC.

Development/

Quality Control Center

-

SEM / Scanning Electron Microscope

It is possible to observe cross section, and to analyse of foreign component.

-

Microscope

Structure Observation & Enlarge Observation is possible. Maximum 1000 times enlarged color photograph is available.

-

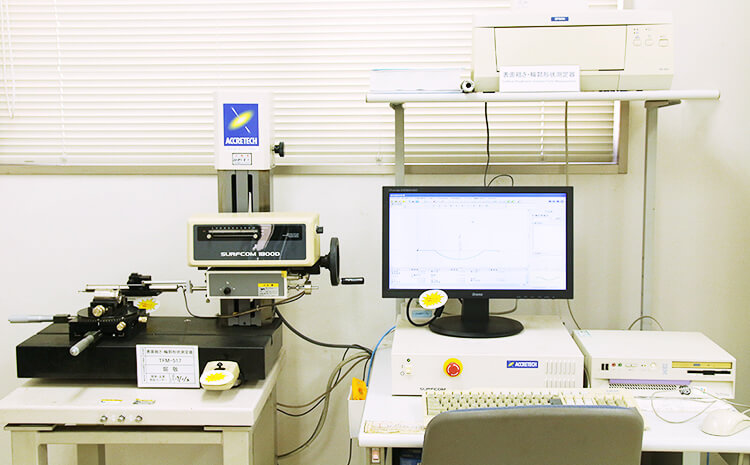

Surface roughness and contour shape measuring machine

Surface roughness indicated on drawings and R forming on metal sheets, which were previously impossible to measure, can now be measured and evaluated by external visual observation.

Certificates

PED(Pressure Equipment Directive)

This is the legislation on the design/manufacture of pressure vessels in the European market (within the EU).

Conforming products can be marked with the "CE" mark.

ISO10380:2012

It is the leading international standard for flexible tube that specifies design,

manufacturing, and testing methods for corrugated flexible metal hoses and hose assemblies.

Hose Type Classification

Type 1-10 : 10,000 life cycles and flexible class

Type 1-50 : 50,000 life cycles and flexible class

Type 1-10 was certified for tube type SA-SD Size DN8 - DN50 & OM-SD DN25 - DN100 on 6th September, 2019.

Type 1-50 was certified for tube type SA-SD Size DN8 - DN50 on 7th August, 2023.

We are preparing to get the certification for High pressure tube type, SA-HP & OM-HP now.

We have 5 welders and 24 welding methods certified by third parties, which are required for PED and ISO10380 certification.

This is an official recognition of our products and quality management system by global standards, as well as a license to export to Europe and the rest of the world.

We will continue to improve our technology and quality to offer to our customers.

International Organization for Standardization

| Qualification / Authentication | Certificates |

|---|---|

| type approval of ISO10380 certification (SA-SD(3)) | |

| type approval of ISO10380 certification (SA-SD 1-50) | |

| type approval of ISO10380 certification (SA-SD 1-10) | |

| type approval of ISO10380 certification (OM-SD 1-10) | |

| factory approval of ISO10380 certification | |

| PED | |

| ISO9001:2015 | - |

| ISO14001:2015 | - |

Type approval by Classification Society

| Qualification / Authentication | Certificates |

|---|---|

| Class NK | |

| Bureau Veritas The factory approved | |

| DNV GL The welding factory approved | |

| Lloyd's Register | |

| The Korean Register of Shipping | |

| The American Bureau of Shipping | |

| China Classification Society | |

| China Corporation Register of Shipping | |

| The Royal Institution of Naval Architects |

Fire Equipment and Safety Center of Japan

| Qualification / Authentication | Certificates |

|---|---|

| Certified the performance of Flexible hose for High Pressure Water Pump Device as Fire Protection Eqipment | |

| Certified the performance of Flexible metal hose | - |

| Certified the performance of Fire protect, Dual Flexible metal hose | - |

Japan Water Works Association

| Qualification / Authentication | Certificates |

|---|---|

| Registrated the factory by Japan Water Works Association(Registration No.0-64) | |

| Certified Flexible hose for Water supply system |

Japan Inspection Association of Food and Food Industry Environment

| Qualification / Authentication | Certificates |

|---|---|

| Bioflex and Corroflon passed the dissolution test | - |

The High Pressure Gas Safety Institute of Japan

| Qualification / Authentication | Certificates |

|---|---|

| Approved the welding procedure test | - |