Technology

Challenging the World

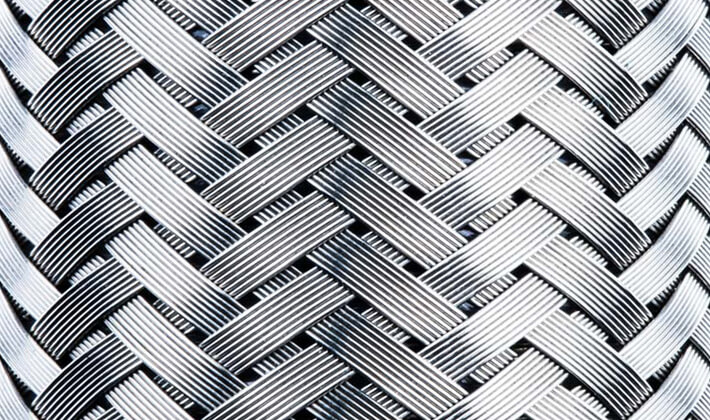

We succeeded in developing Japan’s first corrosion-resistant, durable, low-cost stainless-steel flexible tube. Since then, we’ve continued to take on challenges with the goal of creating world-class flexible tubes that won’t be outshined by countries possessing advanced flexible tubes in Europe.

TOFLE’s Technology

We possess the technologies we have thanks to relentlessly pursuing improvement of flexible tube capabilities—including technology to generate shapes uniformly, to form metals with numerous layers, to manufacture long tubes with no seams from small-diameter to large-diameter, and to handle a wide range of low and high pressures—with an attitude of “no compromises” to win customers’ reliance and trust.

Handling Extreme

Conditions and

Environments

Not only have we developed products to respond to conditions such as increasingly high-altitude construction and equipment as well as high and ultra-high pressurization, but we’ve also worked extensively on craftsmanship for environments that are environmentally friendly.

Aiming for

Further Expansion

We won’t stop with the domestic market; we’re aiming for further expansion by forming TOFLE Group a large presence overseas. To pursue flexible tubes with superior capabilities as well as the limitlessly expanding possibilities of flexible tubes, we will continue to take the challenges of new technologies.

TOFLE OMEGA

FLEX CO., INC.

Hagi, Yamaguchi Prefecture, Japan – A Place where Technology Gathers

Manufacturing technology, development technology, and quality verification systems gather here. Businesses are developing here with an eye toward the rest of the world.